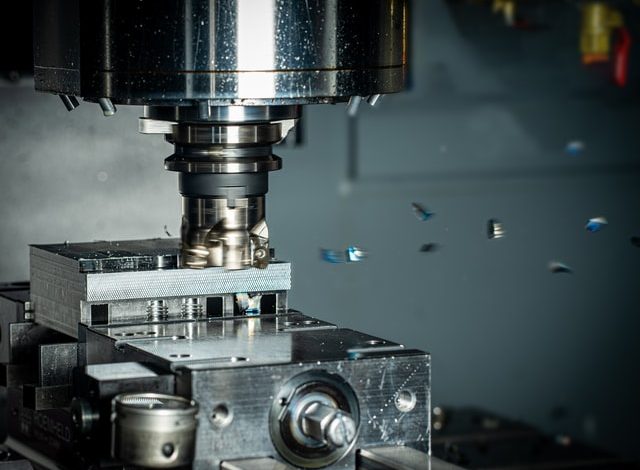

The machine tool industry is a very huge place for the manufacturing of machinery products.

Several necessary components and machine parts are under this industry. According to research, the use of CNC machining is likely to increase up to 6.7% by 2028.

Not only this, with the advancements in modern technical machinery, industries have raised their standards. Now, people can easily shape their required materials with high precision and accurate pressure ranges.

Different components play a vital role in the machining system and the tube bearing is one of them. In this article, you’ll learn how to use these bearings and their different types.

What is Tube Bearing?

In the machine tool market, several crucial components assist in giving shape and dimensions to the products. One of these types of equipment is tube bearing. To speed up the process of manufacturing, high-quality bearings are thereby used in machinery.

The bearings not only make the process more faster and reliable but also improves the functionality of the machine tool spindles. Thus, with the help of these tube bearings, you get a high rate of production and reduced wear and tear parts.

Why are Bearings in demand in the machine industry?

Do you know the revenue of CNC machining can increase to approximately $115 billion dollars in the next four years? This means that there will be high demand for the products made with this latest machinery.

This increasing hype in the lethal and CNC market indicates the over-competitive environment in the future. Thus, tube bearing will also be in more demand as they make up a very important part of the machinery.

Now, you’re well aware of the use and advantages of bearings in the machine industry. So it’s time to discuss the most commonly used tube bearing or the types of bearings.

Types of Tube Bearing Used in Machinery

Whether you use linear bearing or square tube bearing, the size, dimensions, and material should be perfect in each case. Otherwise, you can run into trouble while manufacturing the services or products.

Hence, depending upon the size of the tube bearing, its thickness, and durability, you can choose the one according to your needs. So, while using the tube bearing, you should focus on the chrome finishing, material, and technique used.

To withstand pressure, high speed, and temperature, bearings are widely in use in the machine industry. Four different categories of tube bearing are included in this process. Let’s discuss them in detail.

1- Angular Contact Tube Bearing

The most common tube bearing among spindle bearings is the angular contact ball. One or more rows of rolling balls make up these rolling bears that are then used for certain applications.

The plus point is they are in between the concentric grooved rings and thus can rotate in one direction. Both the axial and radial axis can load in one direction with these bearings and the load-carrying capacity is also determined easily.

Following are the common use of angular contact ball tube bearing;

- You can determine the angle at which the angular ball contacts the bearing.

- The radial and axial load carrying capacity is also determined by this bearing.

- By measuring the angle, the load capacity can also be measured as they are dependent on each other.

Hence, angular ball bearings are very helpful in different applications. Because they are highly efficient and produce high-quality results.

2- Rolling Element Tube Bearing

These are the other types of bearing that are most widely used in the machining industry. Rolling element tube bearing are more effective because its easier to roll a wheel than to slide it on the floor. Moreover, a rolling wheel produces less friction.

The unique feature is that they consist of two rings. One is the inner ring and the other is the outer ring. These inner and outer rings have rolling balls in between them just like angular contact bearings.

However, the main difference lies in the axis of these two bearings. The angulartube bearing can carry the load in one direction only. On the other hand, the rolling tube bearing can move in both axial directions and carry the load.

Thus, rolling tube bearing are highly versatile, or you can say even more diverse than the angular contact bearing.

3- Ball Bearings

Another commonly used type of bearing cover is ball bearing. The most important feature of this bearing is that they do not use rings in their composition.

Instead, they are trapped between two metal pieces that are annulus shaped and contain rolling cylinders that are useful in various applications. Other than this, these rolling cylinders also provide support for the radial and axial axis in one direction.

So, if you’re looking for a tube bearing that reduces friction and provides high-speed products, then ball bearings are the first option. They easily carry the load parallel to the axial and radial axis.

4- Thrust Ball Tube Bearing

For those who are looking for high-precision thrust load equipment, the thrust ball bearing is a perfect fit for them.

This is a highly exceptional tube bearing that provides heavy-duty support. Moreover, its also used in different bearing applications. To carry the load across the axial and radial axis, high-quality driveshafts particularly used.

Depending upon the type of application, different types of rolling elements are available. Some of them are as follows

- Rolling ball

- Roller

- Rolling needle

So, to make precise products and run different applications including propeller engines, thrust ball bearings are very useful. The reason behind its high-efficiency rate is its support of free and easy movement features.

Conclusion

In the end, the use of tube bearing is in high demand nowadays as every industry and machine tool production company is taking benefits from it. Greater efficiency and high precision rates of these bearings make them more useful to use in the machining industry.

As the CNC machining and Lethal industry are growing over time, you can guess that its use and demand will further increase in the future. The manufacturing of cutting-edge products, advanced steel alloys, and related products depends on the bearings you use in machining.