With the evolving times, the CD/DVD pack CD/DVD packaging has also evolved. The most popular CD/DVD storage options concerning CD packaging, Australia, are corrugated CD boxes, cardboard CD boxes, and archival CD boxes. Why Is Cardboard The Best Packaging Material for CDs

The custom CD packaging with cardboard CD storage boxes protects the compact disks during transportation from scratches and other damages from exposure.

The other option would be plastic CD packaging in multiple types, including jewel cases (traditional & slimline) made from polystyrene/polypropylene and thin plastic sleeves. However, plastic cases are one of the significant causes of packaging emissions that harm the environment.

Is Packaging with Cardboard CD Sleeves, Australia, a Better Choice?

Even with the CD usage gone down in recent times, you will be surprised to see the number of CDs still used. Making it even more crucial to prioritize the environment and choose an eco-friendly packaging system. A vast percentage of CD pollution can be evaded if recycled cardboard CD packaging is used instead of plastic compact disc packaging as it reduces packaging emissions.

Also, unlike a plastic CD case, the custom printed CD cases made out of cardboard does not break or damage the discs with scratches. And the unique packaging sleeves australia is safer and secure for transport through postal services.

Hence we can clearly say that CD packaging concepts have grown immensely with the latest technology and moved ahead of plastic CD cases. And considering ecology, CD packaging has gone even more eco-friendly with recycled cardboard, paper and even wood, among other materials.

Now that we know CD cardboard packaging is preferable to plastic CD packaging, it is time to understand further “Why is Cardboard The Best Packaging Material for CDs?”

Types of Cardboard Compact Disk Packaging:

There are four types of cardboard compact disk packaging are as follows:

- Digipak

- Card CD Sleeve

- Gatefold Wallet

- Recycled CD Packaging

Let us see how distinguished each of the above cardboard compact disk-packaging types are.

Digipak: Like a plastic jewel case, the Digipak is made of a cardboard outer shell, and the inside is made of plastic trays that hold the CDs.

Card CD Sleeve: The cardboard CD sleeves, also called CD jackets, are envelope-type cover CD holders made up of 2 panels and are highly sturdy.

Gatefold Wallet: Being 100% recyclable, the eco wallets, also referred to as foldout wallets, are plastic-free and is an Optical disc packaging type similar to Digipak, but instead of a plastic tray, it consists of a pocket.

Recycled CD Packaging: With an eco-friendly wallet with no plastic and biodegradable, non-toxic, vegetable-based inks, recycled cardboards, this is one of the most CD pollution-free packagings that there is.

How can we be sure that cardboard packaging, with an upper hand being eco-friendly, beats plastic packaging in other ways? So, let’s check out the print options for cardboard packaging.

Cardboard Packaging Print Options:

When it comes to the stock and its finishing, in the end, we can have three types, including the glossy, matte and dull finish.

Gloss: For sharper photos and vibrant colours for your designs with less text, gloss coated stocks are advisable.

Matte: This option is best suited if the compact disc packaging has much text, and as the light in matte stocks is scattered, it makes it easy for the readers.

Dull: Dull-coated stocks are between gloss and matte finishing as they are not as bright as gloss stocks and more vibrant than matte. You get a perfect balance.

While, when it comes to other printing options, it has no options to choose disc packaging options.

Spot UV: A screen-printed process most suitable for a matte background, uses UV to cure the varnish applied. It ultimately provides a little shine, smudge-proofed, high clarity design.

Foil Stamping: Add a little glitter with gold/silver or other coloured foil on the graphical elements with foil stamping on your compact disc packaging.

Embossing: Emphasize your compact disc packaging with raised graphical designs and add dimensions to make your logos/title stand out.

Custom Die Cut: The freedom to customize based on how far your creativity takes you, be it for custom size, shape, design and texture, you get a lot more options with CD cardboard packaging than jewel cases.

On the whole, cardboard can be referred to as the best packaging material for CDs as:

- It provides professional, eco-friendly, custom CD packaging with more or as many options as plastic CD packaging.

- It is cost-effective and reduces the CD pollution transportation emissions and the cost.

We could go on about the same. Our friendly experts are here to help.

Plastic Cases

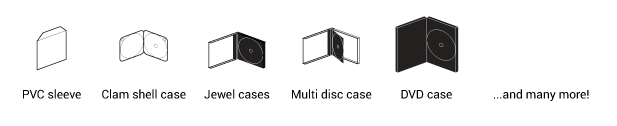

We offer all of the classic case options: jewel cases and DVD cases as well as like the clam shell case and mailer case. Some of the cases we offer:

To see our full range, follow the steps on our quote calculator.

Printed Paper Parts

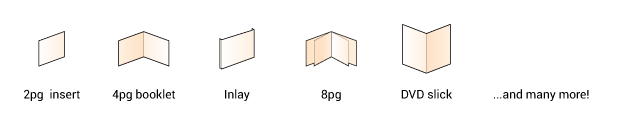

Printed paper parts

Our printed paper parts are some of the best in the business. Whether it’s 2 or 24 pages, 10 or 1000 copies, we deliver outstanding print quality every time. Our paper parts are printed on a Xerox Colour 800 press, one of the most technologically-advanced printers in its class.

To see a full range of the printed paper parts available, follow the steps on our quote calculator.

Printed Card Cases

Short runs

We pride ourselves on producing Australia’s best digitally-printed card packaging. Short runs (less than 500) are offered at large run-quality finishes, thanks to our in-house die cutter. To discover the full range, follow the steps on our quote calculator.

Large runs

When you print runs digi or gatefold cases with us, you have the choice of digital or offset printing.

The digital printing process involves dry toner being fused onto the stock surface. Digital printing produces outstanding mid-tones, crisp text, pure neutrals, detailed shadows, bright highlights and excellent photo rendering.

The offset printing process involves wet ink being applied to the stock surface. Offset printing is how the majority of everyday packaging is printed. It gives a smooth finish, perfect for

reproducing super fine detail.

We believe our digital prints are so good you’ll actually struggle to tell the difference! That being said, offset printing could still be best for you, depending on your artwork and stock preferences.

How Long Does It Take

Short runs (less than 500) can be ready in 2-3 working days.

Large runs (more than 500) which are digitally printed can be ready in 7-10 working days.

Large runs that are offset printed can be ready in 10-15 working days.

We’re happy to accommodate urgent requests where possible, just contact one of our sales staff.

Source: Why Is Cardboard The Best Packaging Material for CDs