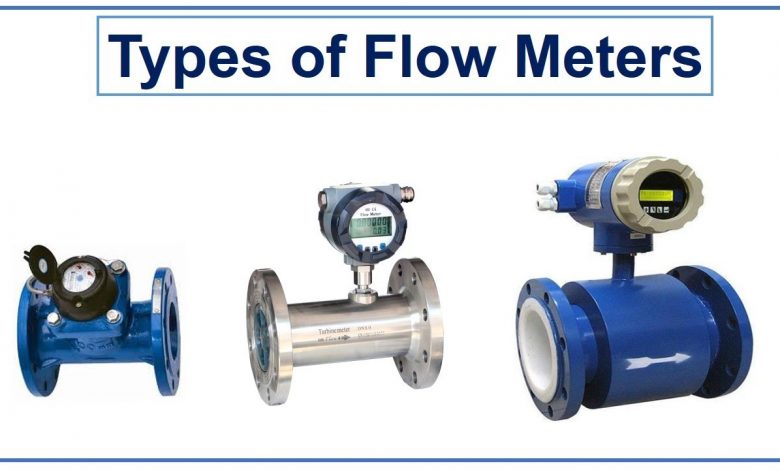

Process Automation Flow Technologies: Flow Meters

Flow meters are popular instruments used in process automation, and they help control the flow of liquids, gases, and fluids. A flow meter can also measure the flow of linear, nonlinear, and mass of several fluids. You can measure the flow of liquids in a pipe using different types of flow meters. Flowmeters, however, have other working principles. Therefore, ensure that you use these meters for the proper application. Here are some of the most popular flow meters in the market.

Flowmeter Types

Flow measurement is essential in several industries. Most companies use flow rates to know if they are making losses or profits. This means that inaccurate flow measurements can lead to a disastrous outcome. Most meters determine the flow of liquids by measuring the speed of fluids or kinetic energy.

Differential Pressure Flow Meters

These meters are commonly used in determining the liquid flow. They are among the most accurate meters. Their operating principle is based on the state that the pressure drop over the meter is directly related to the flow rate pressure. You will get the flow rate if you measure the differential pressure and find the square root.

These meters also have primary and secondary parts. The natural features make a difference in kinetic energy, while the second one determines the differential pressure and then gives the signal, which is changed into the natural flow value.

Orifice Plate

These meters are the most loved ones in the market today. An orifice plate is a flat metal that has a particular hole bored in it. You will install this meter in the middle of two flanges. Acting as the primary device, the orifice Plate will constrict the flow of fluids to make a differential pressure over the pipe. The main advantage of these meters is that they do not have moving parts, and their costs will not increase with the increase in the line.

There are also new units of orifice flowmeters, and they include conical and quadrant orifice. These meters were mainly created to determine the flow of liquids that have low Reynolds numbers. The accuracy of these meters depends on the installation process and also the properties of fluids being measured. Therefore, ensure that the meter is well installed to prevent you from getting losses due to leakages.

Venturi Tubes

Venturi tubes are the best because they can measure the massive flow of liquids at tiny pressure drops. Venturi tubes have a tapered entrance and a line throat. When the liquid goes in, the energy increases, producing a differential pressure in the inlet and outlet regions. Venturi meters do not contain moving parts, and so you can install them in larger diameters using any fittings like flanged, welded, or threaded. Venturi tubes can measure thick or corrosive fluids because they do not contain moving parts.

Turbine Meters

These meters are popular because they have high accuracy levels. These meters have a rotor with several blades fixed with a pipe related to the flow of liquids. When the fluids go through the edges, the speed at which the rotor is rotating is linked directly to the flow rate, and you can use a photocell or a magnetic pick-up to sense it. To get the best measurements, make sure to install them well and also make sure you measure less dense fluids.

Final Thought

A flowmeter is an essential device because flow control is now the key focus for increasing the quality and reliability of the water supply. Lack of attention during the installation process affects flowmeters because they might leak and give poor accuracy. Therefore, ensure that you are attentive when it comes to the installation process of these meters.