Restore Your Sewer System Without Digging: The Advantages of Pipe Lining

Dealing with sewer or drain line issues is never pleasant. For decades, property owners have dreaded the thought of repairing underground pipes because of the disruptive, costly excavation required. Fortunately, trenchless technology has evolved to offer an efficient, minimally invasive alternative: Pipe Lining. This innovative solution allows for the repair of damaged or deteriorated pipes without tearing up your yard, driveway, or flooring.

What Is Pipe Lining?

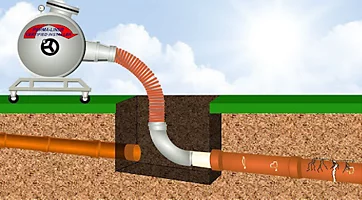

Pipe lining, also known as cured-in-place pipe (CIPP) lining, is a trenchless method used to rehabilitate old, cracked, or corroded pipelines from the inside out. The process involves inserting a flexible liner saturated with a special resin into the existing pipe. Once the liner is in place, it is inflated and cured using hot water, steam, or UV light, forming a solid, seamless new pipe within the old one.

This new “pipe within a pipe” restores structural integrity and flow capacity without the need to dig up and replace the original line.

When Is Pipe Lining the Right Solution?

Pipe lining is suitable for a wide variety of plumbing issues, including:

- Cracked or fractured sewer lines

- Corrosion from age or chemicals

- Infiltration by tree roots

- Minor joint misalignments

- Scaling or buildup inside old pipes

It is ideal for both residential and commercial properties, and works with a range of pipe materials, including cast iron, clay, PVC, and concrete.

Benefits of Pipe Lining

The popularity of pipe lining has surged in recent years, thanks to its many advantages:

- Minimal Disruption: No major digging or demolition is required, meaning your landscape, hardscape, and interior finishes stay intact.

- Cost-Effective: While the initial cost may be comparable to traditional methods, you save big on restoration and cleanup.

- Durability: The new pipe liner is seamless, corrosion-resistant, and rated to last 50 years or more.

- Faster Repairs: Most pipe lining jobs can be completed in just a day or two, with minimal interruption to your water service or business operations.

- Improved Flow: The smooth interior of the new liner reduces friction, improving the overall efficiency of your plumbing system.

- Eco-Friendly: With less equipment, excavation, and waste, pipe lining has a smaller environmental footprint.

The Pipe Lining Process

Here’s a step-by-step overview of how pipe lining works:

- Inspection: A video camera is used to examine the inside of your pipes and determine the extent of damage.

- Cleaning: High-pressure hydro jetting is typically used to clear out debris, roots, and buildup.

- Lining Installation: A resin-soaked liner is inserted into the pipe and positioned precisely.

- Curing: Heat or UV light is applied to harden the liner, forming a tough, seamless new pipe.

- Final Inspection: Another camera inspection ensures the installation was successful and your system is fully restored.

Why Choose Trenchless Pipe Lining?

If you’ve been delaying pipe repairs because you fear the mess, cost, and time involved, pipe lining is the breakthrough solution you’ve been waiting for. It’s especially beneficial for historic properties, buildings with extensive landscaping, or commercial sites that can’t afford prolonged downtime.

Don’t let damaged sewer lines disrupt your property or business operations. Discover the long-term value of Pipe Lining and schedule a professional evaluation today. With trenchless technology, fixing your plumbing doesn’t have to mean destroying your property—just smarter solutions for a cleaner, quicker repair